Mountain Park at Springfield Rise.

| Client | Lendlease |

| Project Partners | Vee Design (landscape architect), Eureka Landscapes (landscape contractor), Play Force (play certifier) and POMO (design) |

| State | Queensland |

Monoliths rise up in south-east Queensland.

Springfield Rise is a major Lendlease residential development near Spring Mountain, 40 minutes south-west of the Brisbane CBD. The master plan boasts extensive parklands and Fleetwood Urban was initially engaged by landscape architects, Vee Design, to progress preliminary designs for an ambitious new custom play structure at Mountain Park in the heart of the fast-growing community.

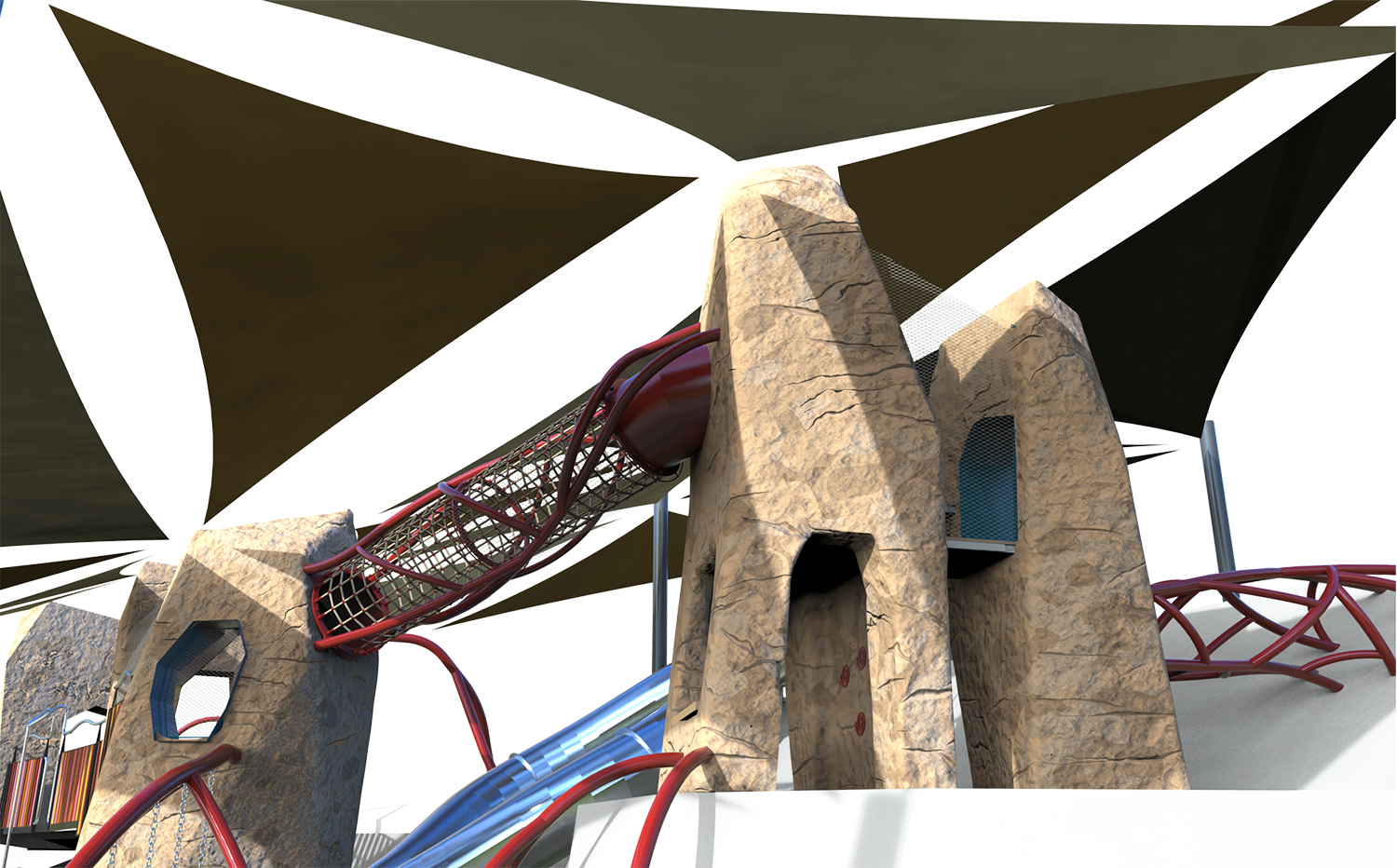

Featuring more than 25 unique moments of play and a figure eight junior play area, the creative centrepieces were five giant stone-like monoliths ranging from 4 to 5 metres tall. After successfully completing design detailing for the project, we were subsequently awarded the construction contract to manufacture and install the structures, novated under the lead landscaping contractor, Eureka Landscapes.

Whilst a complex project requiring painstaking attention to detail from our design, pre-construction and manufacturing teams, the end result was a spectacular success, with the towering monoliths shaped using an innovative and highly sustainable material, Glass-Reinforced Concrete (GRC).

A 5-metre footbridge bridge was also delivered as part of the project, providing safe access across the nearby creek. Mountain Park officially opened in mid-2024.

Our involvement.

Having collaborated successfully on a previous Lendlease project, Fleetwood Urban was approached by Vee Design to help progress their preliminary Play concepts for Mountain Park. Guided by our proprietary design and pre-construction methodology, we explored a variety of options to identify and detail the most effective way to realise their overall creative vision, whilst also working within the parameters of the site and liaising with independent play auditors to ensure all relevant Australian Play Standards were met.

Rigorous estimating and cost control was another feature from start to finish, with significant inflationary pressure (e.g. global prices for structural steel rose by more than 70% during the project window!) challenging the budget at almost every stage.

The key manufacturing and pre-assembly stages were conducted off-site, before the monolith sub-structures were carefully transported to Springfield Rise by truck. They were then shaped, in situ, by a team of GRC specialists before being hand-painted with a faux sandstone finish and then integrated with the other play elements.

-

Design Challenge

Drawing inspiration from the site’s millennia-old rock formations, Vee Design’s concept was exciting - but also hugely challenging to design and detail in a way that could actually be realised. Our Design and Pre-Construction teams worked hand-in-hand with Vee Design and Lendlease to explore different iterations of their concept, together with the methodology required to successfully deliver it within the project budget.

The approved design featured five custom monolith structures interconnected with a series of footbridges and climbing frames, interwoven with ‘strangler vines’ that helped to naturally frame the different play experiences and features within the park - all while maximising accessibility and the natural terrain of the site.

Given the desired size and shaping of the giant monoliths, materiality was an especially critical design consideration, with Glass-fibre Reinforced Concrete (GRC) chosen due its high strength, lightweight and almost endless shaping qualities - something that allowed to design to mimic the appearance of natural sandstone and blend into the surrounding landscape. Shadow studies were another key requirement from Lendlease. All up, the project saw us generate more than 11,000 separate concept and detail design files!

-

Construction Challenge

This was a large and very complex play structure, featuring a series of highly intricate custom elements that needed to connect seamlessly. Precision craftsmanship was absolutely essential. A multi-stage manufacturing process was also required with the main monolith substructures painstakingly fabricated by hand before being wrapped in wire mesh. This process alone required more than 3,000 fabrication hours.

The substructures were then carefully transported and installed at Springfield Rise, before being finished in situ by artisan crews skilled in the use and shaping of GRC. The steep terrain also presented its share of construction challenges, with a network of 85 separate concrete piers required, many founding directly into rock.

-

Innovations

By far the most significant innovation at Mountain Park was determining the best way to create the monoliths. We tested numerous options, including the use of Corten folded steel cladding and pre-cast full concrete options, both moulded on and off site. After considerable exploration and analysis, GRC was chosen both for its creative and cost suitability on the project. An innovative yet relatively underutilised concrete alternative, it was able to be shaped into almost any form, providing the perfect material to cast the imposing monolith structures, without adding unnecessary weight or embodied carbon to the project footprint.

The shop detailing stages also required extensive use of parametric modelling software to optimise the shape of the complex root structures (inspired by the ‘Strangler Fig’) and curving steel elements to minimise wastage. This was a hugely technical process that would have been virtually impossible using conventional design methods.

-

Features

- 5 x giant monolith support structures (3.3m – 4.7m)

- 2 x monolith cubby spaces (2.5m & 3m high)

- Winding ‘figure eight’ Junior Play structure

- 3m cargo tube net climb

- 2.5m viewing deck/bridge

- 5m pedestrian bridge

- Twin stainless steel ‘racer’ slides

- Access ramp

- Retaining wall

- Wonky root flying fox and swing-set

- Pommels, firepole and rock climb

- Musical elements including xylophone, talk tubes and bongo drums

-

Materials

- Structural steel

- Wire mesh

- Glass-fibre reinforced concrete (GRC)

- Rubber soft fall

- Shade sails

- Sandstone blocks

- Modwood decking

- Aluminum balustrades

- Two coat polyurethane paint system

-

Safety & Risk Considerations

Safety was absolutely paramount in the design of the play structures, and also in the way they were created and installed on site. Particular energy was dedicated towards identifying materiality and play flows that could work safely within the site’s steep topography. Independent play certifiers were engaged throughout the design and delivery process to remove potential entrapment and fall risks.

Detailed lift and transport studies were also completed prior to installation on site, ensuring the monolith frames were delivered, shaped and installed without incident. This was another key advantage of specifying GRC on the project, as it significantly reduced the weight of the main structures – making them far easier and safer to lift and manoeuvre.

-

Sustainability Considerations

The use of lightweight GRC allowed the design team to eliminate the need for concrete in the main structures, without compromising on aesthetics or structural integrity. Hot dip galvanising was also used to protect the critical steel elements from corrosion and deliver an impressive 50-year design life.

Visit Mountain Park at Springfield Rise:

Other

Projects.

Explore

Certifications

Environmental Management : ISO14001

Quality Management : ISO 9001

OHS Management : ISO 45001

All Rights Reserved | Fleetwood Urban | Privacy Policy